In the intricate world of manufacturing, precision is paramount, especially when it comes to fittings and connectors. These components, though small, play a crucial role in the functionality and integrity of various products and systems. At the forefront of producing these essential parts are injection mould manufacturers, who combine precision engineering with advanced technology to deliver high-quality fittings and connectors.

The Critical Role of Fittings and Connectors

Fittings and connectors may be small, but their impact is significant. They are essential in ensuring the stability and functionality of various systems, from plumbing to electrical networks. Injection mould manufacturers understand the critical nature of these components and employ meticulous processes to ensure their precision and reliability.

Advancements in Injection Moulding Technology

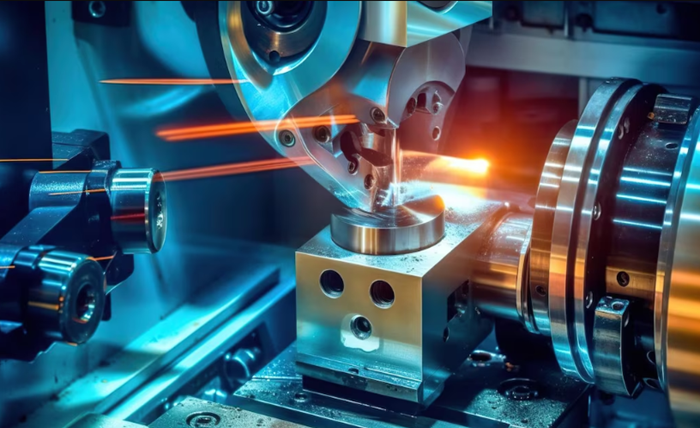

The field of injection moulding is constantly evolving, with new technologies and materials emerging regularly. Injection mould manufacturers stay at the cutting edge of these advancements, utilizing the latest machinery and techniques to produce fittings and connectors that meet the highest standards of quality and precision.

Custom Solutions for Diverse Industries

Different industries have unique requirements when it comes to fittings and connectors. Injection mould manufacturers excel in providing custom solutions, tailoring their processes to meet the specific needs of each industry. Whether it’s a connector for a medical device or a fitting for an automotive application, these manufacturers have the expertise to deliver customized components that perfectly fit the intended application.

Collaborative Expertise: Molding Manufacturers and Injection Molding Supplier

Collaboration is key in the manufacturing sector. Many injection mold manufacturers work closely with molding manufacturers and injection molding suppliers to ensure that every aspect of the production process, from material selection to final output, is optimized for quality and efficiency.

This collaborative approach ensures that the fittings and connectors produced are not only precise but also align with the latest industry standards and trends.

Sustainability and Ethical Manufacturing

In today’s world, sustainability and ethical manufacturing practices are increasingly important. Injection mold manufacturers are adapting to these changing demands by implementing eco-friendly practices, such as using recycled materials and reducing waste in their production processes.

By prioritizing sustainability, these manufacturers are not only contributing to a healthier planet but also meeting the growing demand for environmentally responsible products.

The Global Impact of Injection Mould Manufacturers

The influence of injection mould manufacturers extends globally, with their products being integral to various industries around the world. Their commitment to precision, innovation, and sustainability makes them a vital part of the global manufacturing ecosystem.

Their global impact ensures that industries worldwide have access to high-quality fittings and connectors, contributing to the efficiency and reliability of systems and products across the globe.

In conclusion, injection mould manufacturers play a pivotal role in delivering precise fittings and connectors, essential components in numerous industries. Through their expertise, commitment to quality, and dedication to sustainable practices, these manufacturers are not only meeting the current demands of the manufacturing sector but also shaping its future, ensuring that industries worldwide can rely on the precision and quality of their products.